Pipe Cutting

Ductile iron pipes can be cut by a number of methods.

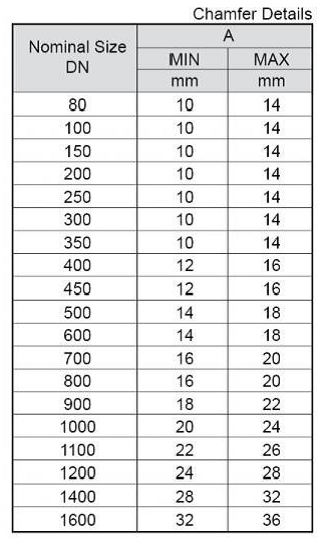

Where flexible joints are to be made, the cut ends must be trimmed with a file or grinder to remove the burn formed during cutting and a chamfer must be provided.

- A Power Driven Abrasive Disc is one of the most widely used methods for cutting ductile iron pipes. It has the advantage of being suitable for all sizes. There is no need for adjustment to suit the pipe or attach machinery to the pipe. The abrasive disc is fitted to suitable handheld power tools usually driven by compressed air or small internal combustion engines.

- It is important when ordering abrasive disc cutting equipment to state that it is for use with ductile iron pipe and to ensure that the disc type and size and the spindle speed of the equipment are compatible.

- Semi-Rotary Wheel Type Cutters are available, ranging from the standard chain link cutters to more sophisticated tools employing a rigid hinged frame. With this type of equipment, it is important to ensure that wheels specifically designed for use with ductile iron are employed. This type of cutter is normally used on pipes the smaller diameters.

- Rotary and Orbital Pipe Cutters, using cutting tools of the simple lathe to milling saw type respectively, are available throughout the diameter range. Whichever type of cutter is employed the machine is attached to the pipe and the cutting tool is driven around the pipe by means of gears on a chain-link track. The orbital type cutters have the advantages of the larger size of ductile iron pipe in that they are capable of accommodating the ovalities which are sometimes present. Some are also capable of forming the chamfer in the same operation. These types of machines are usually driven mechanically, e.g. by compressed air motor-although for pipes in the smaller diameters a hand-operated windlass may be employed. In machines using lathe-type cutting tools. The cutter heads must have a 7º front rake.

- Reciprocating Power Saws may also be used for cutting ductile iron pipes. These tools are usually electrically driven and for this reason, they are principally used in depots or workshops where a power supply is available.

Ensure the spigot is properly chamfered. If it is a cut pipe it is essential to remake the chamber and ensure that there is a radius to prevent the spigot from displacing the gasket.

Contact us: http://www.environmech.com/p/contact-us.html Website: www.Environmech.com