Our Air Knife Systems are engineered, manufactured and tested to provide 99.9% of liquid, dust, and debris removal from products prior to labelling, ink jet laser coating, packaging, or other secondary operations using a high velocity, high impact air stream.

Our Air knives are available in extruded aluminium or stainless steel with lengths from 2" to 196" with an adjustable gap for better air stream control.

We offer nozzle knives for direct drying, air wipes to match your extrusion profile and wire, and food-grade air knives which are USDA and compliant. In-house engineering expertise allows us to provide a heat source for your high-temperature applications or cold air systems to cool the parts.

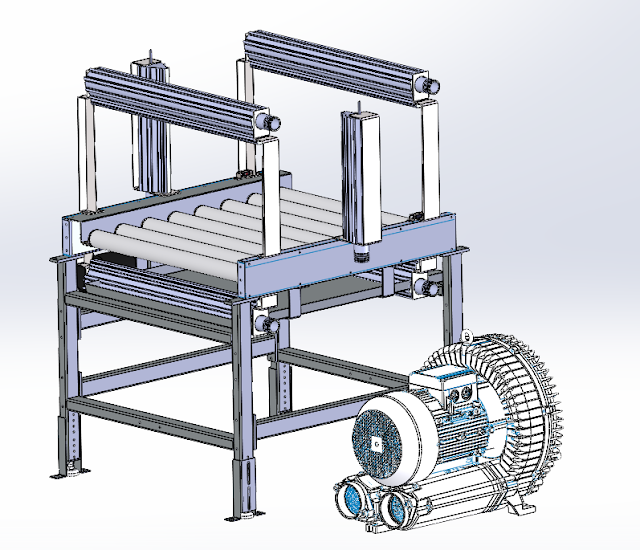

Custom air knife designs are available to meet your exact needs. The breadth of our equipment allows us to engineer and manufacture the additional components needed to complete your system; including the Centrifugal Blower, butterfly valves to provide the appropriate pressure and air stream as needed, and air knife brackets, elbows, Y-branches, and manifolds.

Air Knife Working Principle

An air knife is a pressurized air plenum with a uniform continuous gap that pressurized air exits in a laminar flow pattern. The exiting air velocity creates an impact air velocity directly onto the surface of the product to shear away moisture or particulates without mechanical contact. This impact air velocity can range from a gentle breeze to greater than 40,000 feet per minute.

Our Air Knife Advantages

- Low energy consumption

- Dry, clean, oil-free air stream

- Filtered blower inlet to prevent particle contamination

- Safe, low pressure

- Increased production speeds and output for a quick payback

- Reduced sound levels when compared to compressed air nozzle or round tube design.

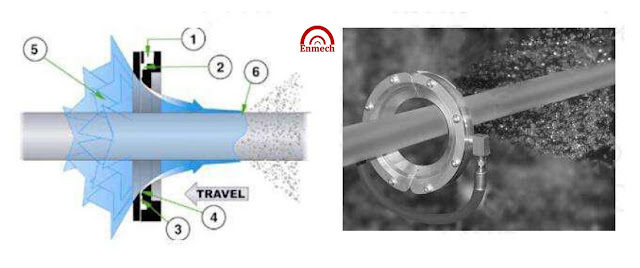

Ring air knife, air knife-it is a professional product for cooling and surface cleaning and drying of electric wires, cables and plastic hoses.

Ring air knife, air knife-it is a professional product for cooling and surface cleaning and drying of electric wires, cables and plastic hoses. Ring air knife, ring air knife, circular air knife, air ring scrubber, ring air knife, circular air knife, air ring, etc. Air scrubbing This product is widely used in domestic and foreign enterprises.

A ring air knife is used to blow, dry, clean and cool pipes, cables, extruded products, hoses or other products.

Equipment, which provides uniform 360 annular airflows. The annular air knife is connected by two curved hinges, which can give a large airflow. Two air knives. Its gas consumption is minimal, but it can produce powerful blowing force. The magnification of the annular air knife is 30:1, and its high-flow airflow can provide cooling and dry for all sides of the product. The ring-shaped structure can generate stable and powerful airflow to wrap around the side of the object so that all water and dirt can be removed.

Compressed air enters the annular cavity.

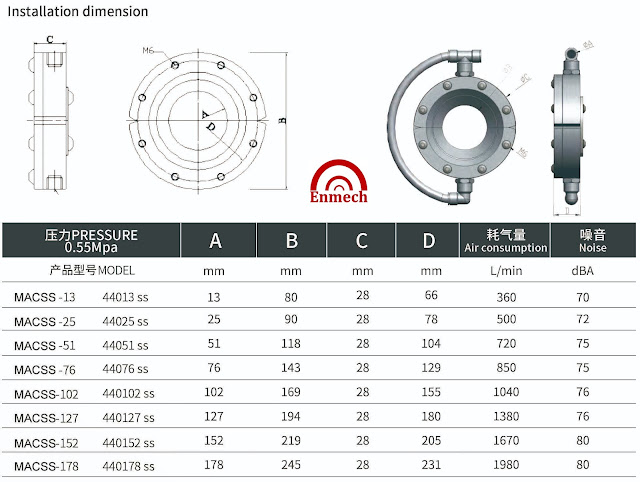

Different types:

Working principles:

(1) Through the inlet

(2) Through the air circulation. Then throttled and passed through the annular nozzle

(3) At a high speed. At first, the air flows out at a high speed along the side wall

(4) This air flows along the side wall of the air ring at an oblique angle. In this way, a low-pressure area

(5) Will be created at the centre of one side of the air ring, and this low-pressure area will force a large amount of surrounding air to flow to the other side of the air ring together with the high-pressure airflow. When the airflow leaves the air ring, a 360-degree conical annular airflow is generated, and this even and powerful airflow can continuously and stably wipe the dirt, water and other impurities on the material

(6) Passing through the air ring.

Advantages:

• Low noise, within 70dB in most cases

• Environmental protection and energy saving, air flow balance

• Suitable for different bottle types, convenient adjustment, fast compression, low air consumption, air compression ratio up to 40:1

• Adjustable air knife and flow

• Structure design open type, compact, firm, easy to install

• No need for electricity, no moving mechanical parts

• Small holes on the edge of the ring for easy installation.

Videos

Sales References (Malaysia)

Air Knife - KA-500-S1-51-1 air knife for stripping of water fibres from blades on a rotary drum, Malaysia

1,600 mm length air knife, dual-outlet for our client from the poly glass industry. It is purchased and installed together with our side channel blower.

Rubber Glove Factory in Malaysia (2023)

Glass Manufacturing Plant, Selangor (2024)

Air Knife - - KA-330-S1-51-1, KA-380-S1-51-1 with Air Blower Model: DHB910C12D5 (F&B Factory, Shah Alam, Box Drying Application. (2025)

Download:

Air Knife (Malaysia) and Drying System

For more information or enquiry, please contact Environmech Sdn. Bhd.

Contact us: http://www.environmech.com/p/contact-us.html

Website: www.Environmech.com

.jpg)